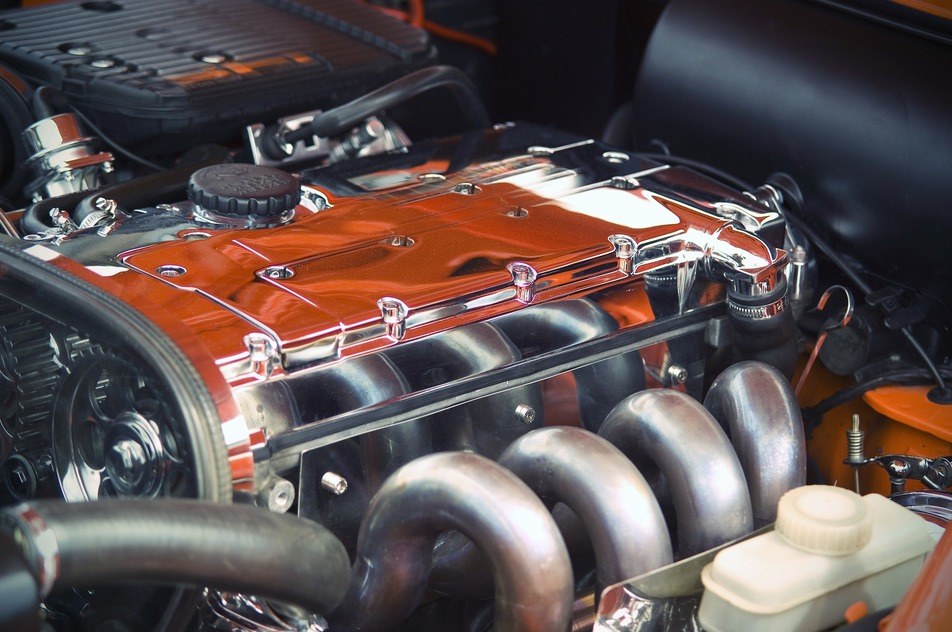

The engine block is often referred to as the backbone of the engine, and for good reason. It houses and supports all the major moving parts of an internal combustion engine. Whether you’re a beginner trying to understand your car’s mechanics or an automotive student diving deeper into engine architecture, knowing the components of the engine block is fundamental.

In this guide, we’ll explore the major engine block components, their roles, how they work together, and why each part is essential to overall engine performance and longevity.

🔧 What Is an Engine Block?

An engine block, sometimes called a cylinder block, is a large, solid piece of metal—usually cast iron or aluminum alloy—that contains the cylinders and many of the key components of the engine. It forms the core structure that supports and holds together various systems in an engine.

In multi-cylinder engines, the block integrates all the cylinders into a single component and provides a framework for lubrication, cooling, and crankshaft support.

⚙️ Main Engine Block Components and Their Functions

Let’s break down the essential components found within or attached to the engine block:

1. Cylinders

- Function: The chambers where the pistons move up and down during the combustion process.

- Details: Most modern engines have 3 to 8 cylinders. The precision of cylinder shape affects compression and engine efficiency.

2. Cylinder Bores

- Function: The inner walls of the cylinders that guide piston movement.

- Details: Often lined with a wear-resistant material like cast iron or nickel-silicon carbide in aluminum blocks.

3. Pistons (Housed within the block)

- Function: Move up and down within the cylinders to convert combustion pressure into mechanical motion.

- Note: While technically not a fixed block component, pistons operate within the block, making their interaction critical.

4. Crankshaft

- Function: Converts the reciprocating (up-down) motion of pistons into rotational motion.

- Mounting: Positioned at the base of the engine block and supported by main bearings.

5. Main Bearings

- Function: Support the crankshaft, allowing it to spin freely and smoothly within the block.

6. Connecting Rods

- Function: Link the pistons to the crankshaft and transfer force during the combustion cycle.

7. Camshaft (in some engines)

- Function: Controls the opening and closing of engine valves.

- Note: In some overhead cam designs, the camshaft is outside the block, but in older or pushrod engines, it’s inside the block.

8. Oil Passages and Galleries

- Function: Internal channels that allow engine oil to reach various moving parts for lubrication.

9. Water Jackets

- Function: Channels around the cylinders that circulate coolant to manage engine temperature and prevent overheating.

10. Deck Surface

- Function: The flat surface at the top of the engine block where the cylinder head attaches.

- Importance: Must be precisely machined to ensure a good seal with the head gasket.

11. Freeze Plugs (Core Plugs)

- Function: Prevent damage from freezing by allowing expansion; also seal casting holes used during manufacturing.

🏗️ Supporting Structures Attached to the Engine Block

Besides internal components, several vital structures are mounted to the block:

- Oil Pan – Bolted to the bottom, it stores engine oil.

- Timing Cover – Protects the timing chain or belt.

- Motor Mounts – Connect the block to the vehicle chassis.

🔍 Why Understanding Engine Block Components Matters

Knowing how the engine block is structured can help with:

- Diagnosing engine problems (e.g., overheating, oil leaks, loss of compression)

- Performing rebuilds or upgrades

- Improving performance through tuning and machining

- Extending engine life with proper maintenance

🔧 Common Engine Block Issues

Over time or under extreme conditions, the engine block can suffer from:

🔸 Cracks

Caused by overheating, freezing coolant, or high stress. Cracked blocks can lead to leaks and loss of compression.

🔸 Warped Deck

Overheating can cause the deck surface to warp, preventing proper head gasket sealing.

🔸 Worn Cylinder Walls

Results in poor compression and oil burning; may require reboring or sleeving.

🔸 Oil and Coolant Leaks

Leaks in internal galleries or seals can lead to cross-contamination and engine failure.

🛠️ Tips to Maintain Engine Block Health

- 🔧 Regular oil changes with the right grade of oil

- 🌡️ Maintain coolant levels and ensure no air bubbles in the system

- 🧼 Keep the engine clean to avoid debris buildup

- 📏 Check cylinder compression periodically

- ❄️ Use the correct antifreeze ratio to prevent freeze damage

FAQs About Engine Block Components

Q1: Can you replace individual components inside the engine block?

Yes, most components like pistons, bearings, and the crankshaft can be replaced or upgraded without replacing the entire block.

Q2: What causes engine block damage?

Common causes include overheating, poor lubrication, detonation, and manufacturing defects.

Q3: Is it possible to repair a cracked engine block?

Minor cracks may be repaired using welding or chemical block sealants, but major cracks often require block replacement.

Q4: What’s the difference between a short block and a long block?

A short block includes the engine block, crankshaft, pistons, and rods. A long block also includes the cylinder head and valvetrain.

Q5: How can I tell if my engine block is failing?

Symptoms include excessive oil consumption, coolant in the oil, overheating, and low compression in one or more cylinders.

Q6: Are all engine blocks made from the same material?

No. Common materials include cast iron (strong but heavy) and aluminum alloy (lighter and better heat dissipation).

Conclusion: The Engine Block Is the Powerhouse Core

The engine block and its components are essential to the operation and performance of any internal combustion engine. From supporting the crankshaft and pistons to housing coolant and oil passages, every component inside the block plays a role in the engine’s power, efficiency, and durability. Whether you’re maintaining your daily driver or building a high-performance engine, understanding the components inside the engine block gives you a powerful edge in keeping your engine running strong for years to come.