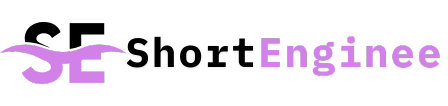

Diesel engines are renowned for their power, fuel efficiency, and durability. From trucks and buses to generators and industrial machines, diesel engines are the workhorses of the world. But just like any powerful machine, they require consistent care and maintenance to operate at peak performance.

In this comprehensive guide, you’ll learn everything you need to know about diesel engine maintenance—including how diesel engines work, the key components to maintain, common problems, expert tips, and a complete maintenance schedule.

🚙 What Makes Diesel Engine Maintenance Unique?

Diesel engines differ significantly from gasoline engines. They operate under higher compression, lack spark plugs, and rely on compression ignition. This makes them more fuel-efficient and longer-lasting, but it also means their maintenance needs are more specific.

Key Differences from Petrol Engines:

- Higher operating pressure and temperature

- More complex fuel injection systems

- Greater sensitivity to fuel quality

- No spark plugs — uses glow plugs for ignition

- Prone to soot and carbon buildup

Maintaining a diesel engine is not just about changing oil—it’s about preserving power, reducing emissions, and extending the lifespan of an engine that can last hundreds of thousands of kilometers when cared for properly.

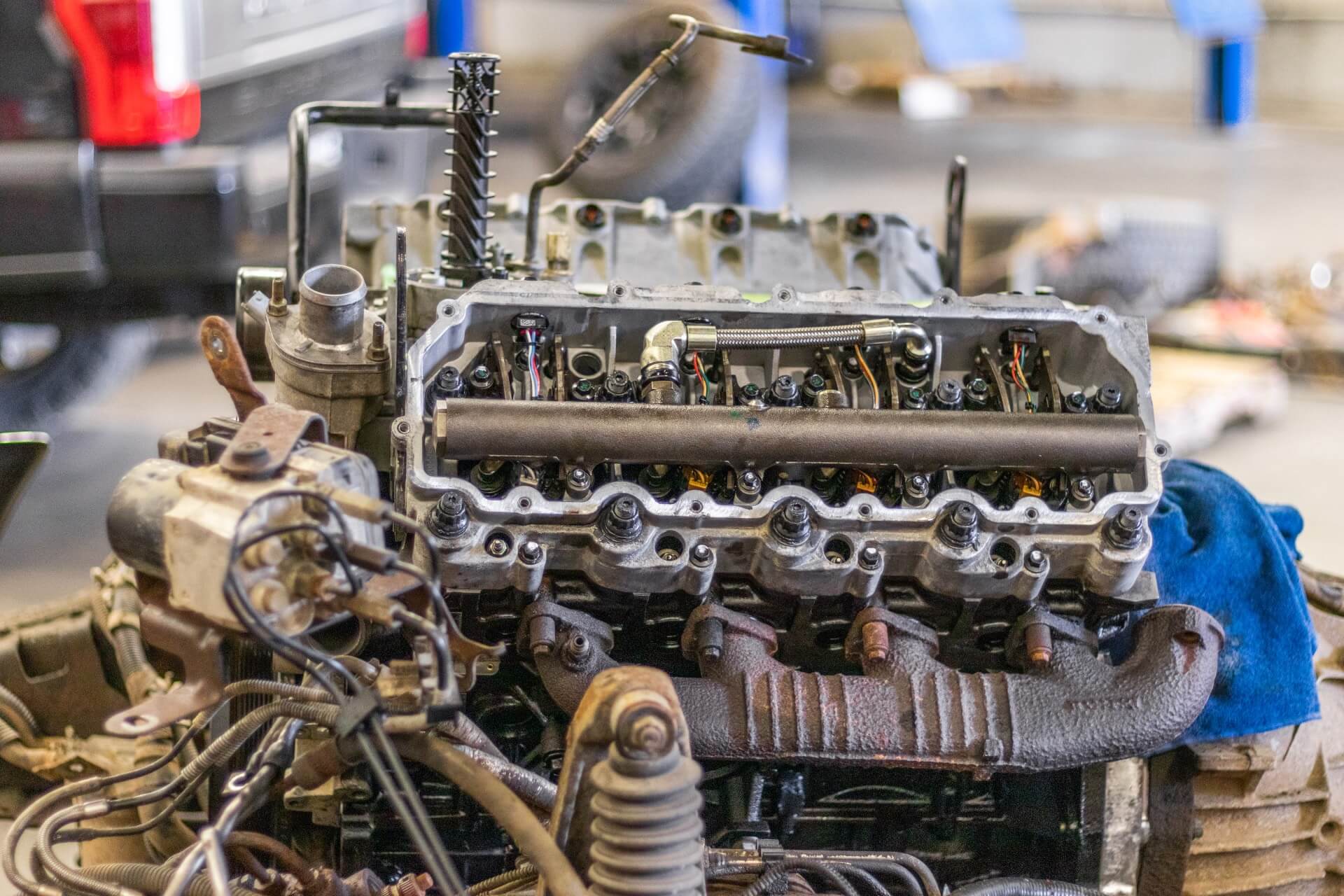

🧰 Key Diesel Engine Maintenance Components and Procedures

Let’s dive deeper into the essential areas that need regular attention in a diesel engine:

🔧 1. Engine Oil and Oil Filter

Diesel engines generate more soot and combustion byproducts than petrol engines, contaminating the oil quickly. That’s why frequent oil changes are critical. Always use high-quality, heavy-duty diesel engine oil, and change it along with the oil filter to protect internal components from premature wear.

Tip: Check oil levels weekly and look for signs of contamination or sludge.

🔧 2. Fuel System and Fuel Filters

Diesel fuel systems are highly pressurized and sensitive. Water, dirt, and impurities in fuel can cause injector damage, power loss, and starting problems.

Key actions:

- Replace both primary and secondary fuel filters regularly

- Drain the fuel-water separator (if equipped)

- Use additives to prevent algae and moisture in fuel tanks

🔧 3. Air Filter Maintenance

Diesel engines need large amounts of clean air for combustion. A clogged air filter can choke the engine, reducing performance and increasing fuel consumption.

Recommendation:

Check the air filter every 10,000–15,000 km, or sooner in dusty or off-road conditions. Replace or clean it when dirty.

🔧 4. Cooling System Care

Diesel engines run hotter and require efficient cooling to avoid overheating and head gasket damage. Key elements include the radiator, thermostat, hoses, and coolant.

What to do:

- Check coolant levels weekly

- Inspect radiator for leaks and blockages

- Flush the system every 2 years or as recommended

🔧 5. Glow Plug Testing and Replacement

Diesel engines don’t have spark plugs; instead, they rely on glow plugs to preheat air in the combustion chamber. Faulty glow plugs can cause starting issues, especially in winter.

When to inspect:

- If starting takes longer than usual

- If the engine misfires on cold starts

- Annually before winter season

🔧 6. Battery and Charging System

Because diesel engines have higher compression, they require more battery power to crank the engine. A weak battery can cause slow cranking or no start.

Battery care tips:

- Check voltage and terminals regularly

- Clean corrosion and tighten connections

- Replace battery every 3–5 years

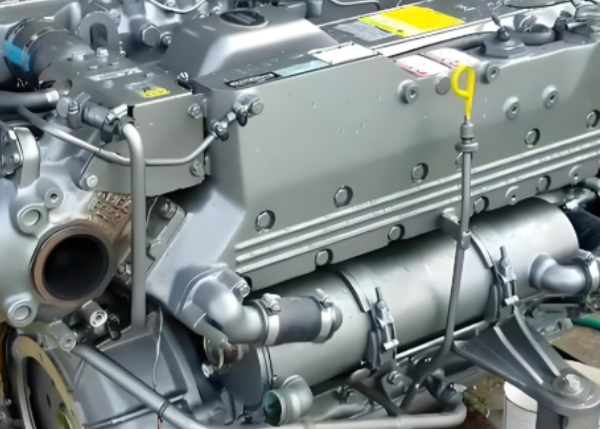

🔧 7. Turbocharger (if equipped)

Many modern diesel engines are turbocharged. Turbos increase power and efficiency, but they operate at high RPMs and heat. Lack of oil or dirty oil can destroy a turbo quickly.

Maintenance includes:

- Using correct oil and changing it on time

- Letting the engine idle for a few minutes before shutdown (to cool the turbo)

- Checking for whining noise or smoke — signs of turbo wear

🔧 8. Exhaust and EGR System

The Exhaust Gas Recirculation (EGR) system reduces NOx emissions but can get clogged over time, leading to power loss and higher emissions.

Maintenance includes:

- Cleaning the EGR valve periodically

- Inspecting the diesel particulate filter (DPF)

- Avoiding excessive idling

🧭 Diesel Engine Maintenance Schedule (General Guideline)

| Task | Frequency |

| Oil & Oil Filter Change | Every 5,000–10,000 km (or as per manual) |

| Fuel Filter Replacement | Every 15,000–30,000 km |

| Air Filter Check | Every 10,000 km |

| Coolant Flush | Every 2 years |

| Glow Plug Inspection | Every 12 months |

| Battery Check | Every 6 months |

| Turbocharger Check | Every 20,000 km |

| Belts & Hoses Inspection | Every 15,000–20,000 km |

| Injector Cleaning | Every 20,000–30,000 km |

Note: Always follow your vehicle manufacturer’s recommended schedule.

⚠️ Common Symptoms of a Poorly Maintained Diesel Engine

Ignoring diesel maintenance can lead to serious issues. Look out for:

- Excessive black, white, or blue exhaust smoke

- Difficulty starting, especially in cold weather

- Irregular engine idling

- Increased fuel consumption

- Loud knocking or unusual engine sounds

- Reduced power or sluggish acceleration

- Frequent stalling or engine shutdowns

If you notice any of these signs, get your engine checked immediately to prevent major damage.

🔧 Pro Tips to Maximize Diesel Engine Life

- Warm up the engine before driving — especially in winter

- Avoid short trips that don’t let the engine reach optimal temperature

- Use high-quality diesel fuel and reputable fuel stations

- Install a pre-filter or water separator if you operate in rural or remote areas

- Don’t ignore warning lights or unusual engine behavior

- Use fuel system cleaners or additives periodically

- Follow the manufacturer’s recommended service intervals strictly

FAQ’s

1. What happens if I delay diesel engine oil changes?

Delaying oil changes in a diesel engine can cause excessive soot buildup, increased friction between parts, poor fuel economy, and eventually engine damage due to lack of proper lubrication.

2. How can I tell if my diesel fuel filter is clogged?

Signs of a clogged diesel fuel filter include hard starting, rough idling, loss of power during acceleration, and unusual engine noise. Regular replacement is key to avoiding these issues.

3. Is it necessary to warm up a diesel engine before driving?

Yes, especially in cold weather. Warming up a diesel engine helps circulate oil properly, activates glow plugs, and ensures smoother performance while reducing engine wear.

4. How often should I clean or replace my diesel engine’s air filter?

Typically every 10,000–15,000 km, but it should be checked more frequently if you drive in dusty or off-road conditions. A dirty air filter can reduce engine efficiency and power.

5. Can bad glow plugs affect diesel engine performance?

Absolutely. Faulty glow plugs can make the engine hard to start, especially in cold weather, and lead to incomplete combustion, rough idling, and increased exhaust smoke.

Final Thoughts

A well-maintained diesel engine can deliver outstanding performance, longer lifespan, and better fuel efficiency. Whether it powers your daily driver, a commercial truck, or industrial equipment, diesel engine maintenance is an investment in reliability and savings. By following this detailed guide, performing regular inspections, and using the right parts and fluids, you can keep your diesel engine running strong for hundreds of thousands of kilometers.